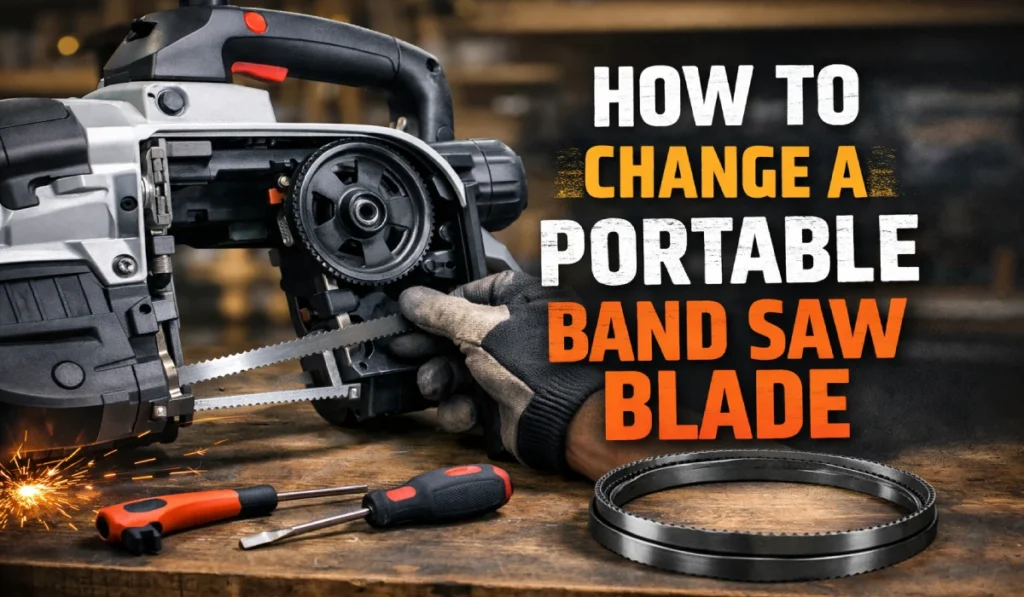

There is nothing quite like the feeling of a portable band saw slicing through a piece of Unistrut or heavy rebar like it’s butter. It is one of the most versatile tools in the truck, whether you are a plumber, electrician, or a carpenter handling onsite fabrication.

But we have all been there: You are in the middle of a cut, pushing harder than you should, and you smell it. That hot, metallic scent of friction. The saw starts to wander, the motor bogs down, and you realize you are basically just polishing the metal rather than cutting it.

Your blade is toast.

Changing a portable band saw blade is a fundamental skill, but you would be surprised how many guys get it wrong. They put the teeth on backward, they don’t seat it in the guides correctly, or they snap the new blade before it even touches the workpiece.

I’ve spent years on jobsites and in the shop, and I’ve swapped out more of these bands than I can count. Today, I’m going to walk you through exactly how to change a portable band saw blade the right way, troubleshoot common issues, and get the maximum life out of your new cutter.

Signs It’s Time for a Change

Before we start tearing the tool apart, let’s make sure you actually need a new blade. We don’t want to throw money away, but running a dull blade is hard on your tool’s motor and dangerous for you.

Here is what I look for:

- The “Wander”: If you are trying to cut a straight line and the blade keeps drifting to the left or right no matter how steady you hold it, the teeth on one side are likely duller than the other.

- Stripped Teeth: This usually happens when cutting thin-walled conduit with a coarse blade. If you hear a rhythmic thump-thump-thump during the cut, you’re missing teeth.

- Excessive Heat: If the workpiece is glowing red or smoking excessively (and you aren’t forcing it), the blade isn’t cutting; it’s rubbing.

- Hairline Cracks: Inspect the gullets (the valleys between teeth). If you see tiny fractures, that band is about to snap. Change it immediately.

Safety First: The “Lock Out” Rule

I cannot stress this enough. Portable band saws are torque monsters. If you accidentally hit the trigger while your fingers are inside the housing, you are going to have a very bad day.

- Corded Tools: Unplug it. Don’t just rely on the trigger lock.

- Cordless Tools: Drop the battery. Physically remove it from the tool.

- Gloves: Usually, I tell people not to wear gloves near spinning machinery. However, when changing a band saw blade, the machine is off. New blades are razor-sharp and often coated in oil. Wear cut-resistant gloves to protect your hands while handling the band.

Step-by-Step: Changing the Portable Band Saw Blade

This process is roughly the same whether you are running a Milwaukee, DeWalt, Makita, or a compact sub-compact model. The mechanics are universal.

Step 1: Release the Tension

Flip the saw over so the pulleys are facing you. On the front of the saw (usually near the handle or the center of the body), you will see a large tension lever.

Rotate this lever 180 degrees. You should feel the tension release immediately. The blade will go slack around the wheels. If your saw has a blade guard that covers the wheels, you may need to loosen a couple of screws or flip a latch to expose the pulley tires, but most modern saws expose enough of the wheel to do this without tools.

Step 2: Remove the Old Blade

With the tension released, the blade should slide right off. I usually pull it off the rear pulley (the drive wheel) first, then slip it out of the guide rollers, and finally off the front pulley (the idler wheel).

Pro Tip: Take a quick look at the rubber tires on the pulleys. If they are chewed up, cracked, or missing chunks, a new blade won’t track right. If they look rough, order a replacement set of tires now.

Step 3: The “Unfolding” Technique

New band saw blades come coiled up tightly in the package. If you just rip the package open, that blade can spring out like a cobra and smack you in the face. I’ve seen it happen.

Hold the coiled blade with one hand firmly gripping the loops. Carefully peel off the tape or twist tie. Hold the blade away from your face and body, and gently rotate your wrist to let the loops spring open into the full oval shape. Give it room to pop open.

Step 4: Verify Tooth Direction (Crucial!)

This is the most common mistake rookies make. They install the blade inside out or backward.

Look at your saw. There should be an arrow on the housing indicating the direction of the cut. Generally, on a portable band saw, the blade travels toward the rear handle on the cutting side.

This means the sharp points of the teeth should be facing the direction of the cut-usually pointing toward the back of the tool where the material stop is located. If you run your finger (gently!) along the teeth in the direction the blade rotates, it should feel smooth. If you run against the rotation, it should catch your skin.

If the teeth are pointing in the wrong direction, do not panic. You likely just have the blade inside out. Flip the band inside out like a sock, and check the orientation again.

Step 5: Threading the New Blade

This is where finesse beats force.

- Guide Rollers First: I always start by slipping the blade between the guide roller bearings. These are the little metal wheels that keep the blade straight during a cut. There is usually a set near the front and a set near the back. Get the blade seated nicely between them.

- The Pulleys: Loop the blade around the pulleys. The back of the blade (the smooth edge) should be resting against the flange or lip of the pulley tire.

- Fit Check: Ensure the blade is fully seated on the rubber tires and isn’t riding on the metal edge of the wheel.

Step 6: Apply Tension

Once the blade looks centered on the tires and is seated in the guides, flip the tension lever back to the locked position.

Don’t pull the trigger yet.

Step 7: The Manual Cycle

Before you add power, rotate the blade by hand. Grab the blade (carefully) or the exposed part of the wheel and spin it a few full rotations.

You are watching for “tracking.” Does the blade stay centered on the tires? Does it pop out of the guides? If it starts to ride off the wheel, release the tension, adjust the seating, and tension it again. It should run smooth and true.

Breaking in a New Blade: The Secret to Longevity

Most people skip this, and that is why their blades dull out in two days. A new blade has extremely sharp, microscopic burrs on the teeth. If your first cut is slamming into a thick steel pipe at full speed, you strip those burrs instantly, effectively dulling the blade before it has a chance to work.

How to Break it In:

- Reduce Speed: If your saw has a variable speed dial, turn it down to about 50%.

- Soft Start: Make your first few cuts on softer material or thinner stock if possible.

- Light Pressure: Gently ease the blade into the cut. Do not lean on the saw. Let the weight of the tool do the work.

- After cutting about 50-100 square inches of material (or just 5-10 good cuts), you can ramp the speed back up and apply normal pressure. This “hones” the teeth and hardens the cutting edge.

Choosing the Right Blade (TPI Matters)

You wouldn’t use a sledgehammer to hang a picture frame. Similarly, you can’t use one blade for everything. The biggest variable here is TPI (Teeth Per Inch).

- 10/14 TPI (Coarse): This is for thick stock. Think heavy wall pipe, angle iron, or solid bar stock. The deep gullets clear chips fast. If you use this on thin metal, the teeth will straddle the material and rip the teeth right off.

- 14/18 TPI (Medium): The “Goldilocks” blade. It’s great for general purpose cutting-Unistrut, EMT conduit, and standard pipe. If you only carry one blade type, make it this one.

- 18 or 24 TPI (Fine): Essential for thin metals. Sheet metal, thin-wall conduit, or threaded rod. It leaves a very smooth finish but cuts slower.

The Rule of Thumb: You always want at least three teeth in the material at any given time. If you have fewer than three, the blade will snag and strip.

Troubleshooting Common Issues

Even with a new blade, things can go wrong. Here is what the saw is trying to tell you.

The Blade Keeps Popping Off

If you put a new blade on and it throws itself off the wheels immediately, check your tires. If the rubber tires are greasy or worn down, they lose their grip. Clean them with a little denatured alcohol. If they are loose, replace them.

Also, check your guide bearings. If they are frozen (won’t spin) or caked with grime, they will push the blade off track. Blast them with some compressed air and a little dry lubricant.

The Cut is Crooked

You changed the blade, but it’s still cutting crooked? This usually means your guide rollers are out of alignment. Most portable band saws allow you to adjust the angle of the guides with a hex key. If the guides are worn out and have too much “slop,” the blade will twist under load.

The Blade is Bouncing (Chatter)

This is usually a TPI issue. You are likely using a blade that is too coarse for the material you are cutting. Switch to a higher TPI count. It could also mean your workpiece isn’t clamped down securely. Vibration is the enemy of a good cut.

Maintenance: Keep the Saw Singing

Changing the blade is the perfect time for a 30-second maintenance pit stop.

- Blow it Out: Use an air compressor to blow out the metal chips from inside the blade housing. Metal chips can migrate into the motor vents or get stuck between the blade and the tire, causing slippage.

- Check the Cord/Battery Terminal: Look for nicks in the power cord or corrosion on battery contacts.

- Wax the Table: If your portable band saw has a small metal backstop (shoe), keep it clean. A rough shoe can scratch up your material and make it hard to slide the saw smoothly.

Frequently Asked Questions (FAQ)

1. How do I know which direction the teeth should point on my portable band saw?

The sharp point of the teeth should always face the direction of the cut. On almost all portable band saws, the blade moves toward the rear handle (or the user) on the bottom cutting side. If you run your finger gently along the blade in the direction of rotation, it should feel smooth. If it feels rough, the blade might be backward.

2. Why does my new band saw blade keep slipping off?

Slipping is usually caused by worn-out rubber tires on the pulleys or grease/oil on the blade. Inspect the rubber tires on the wheels; if they are cracked or loose, they need replacing. Also, wipe down the new blade and the tires to ensure there is no oil residue interfering with the traction.

3. Can I use a metal cutting blade on wood?

Technically, yes, but it’s not efficient. Metal cutting blades have high TPI (Teeth Per Inch) and small gullets, which clog up instantly with sawdust, leading to burning and slow cuts. If you need to cut wood, look for a blade specifically designed for it with a lower TPI (around 6–10 TPI) and larger gullets to clear the waste.

4. How tight should the blade be?

On a portable band saw, the tension is usually not adjustable by the user-it is set by the manufacturer’s spring-loaded tension lever. When you flip the lever to the “locked” position, it applies the correct factory-spec tension. If the blade feels loose even when locked, your tension spring may be worn out and the tool requires servicing.

5. How long should a portable band saw blade last?

This depends heavily on use. A bi-metal blade can last for hundreds of cuts through mild steel conduit if broken in properly and not overheated. However, cutting hardened steel, stainless steel, or forcing the saw can kill a blade in minutes. To extend life, let the tool do the work-don’t push down hard!

Conclusion

Changing a portable band saw blade isn’t rocket science, but doing it correctly makes the difference between a tool that fights you and one that feels like an extension of your arm.

Remember the basics: Release tension, check orientation, seat it correctly, and break it in.

Treat your saw with respect, use the right TPI for the job, and stay safe out there. Now, put that battery back in and go make some sparks.